Senior Engineer

Victaulic

Tunnels, which occur in many construction projects, present designers and engineers with particular challenges when it comes to installing pipework. Grooved mechanical pipe-joining technology can help overcome these challenges, both during the design and construction phase, explains Dave Hudson, Senior Engineer, Victaulic, the world’s leading producer of grooved mechanical couplings and pipe-joining systems.

Tunnels occur in many construction projects: notably, in major road and rail systems, as well as pedestrian subways, in mines, water and wastewater treatment plants, and even hospital buildings or medical campuses. Frequently long, seldom straight and commonly with access issues, tunnels pose a specific set of engineering challenges. These are chiefly accommodating curvature, directional changes and thermal movement but can also include limited installation time, lack of space to install pipework and a challenging environment.

Then there are the all-important health and safety considerations. The heightened risk of fire and increased difficulty in extinguishing a fire on a tunnelling construction site, along with potential workforce exposure to noxious fumes with some joining methods, makes grooved piping the option of choice.

Mechanical pipe joining

The grooved mechanical pipe-joining system is a safe, efficient alternative which takes up curvature and accommodates thermal expansion and contraction. As a flame-free method, it eliminates not only the dangers associated with hotworks but also the necessary fire watch together with time-consuming job-site preparation, all of which add time and labour costs to a tunnelling project.

At the start of the construction, tunnel boring machinery will need to be supplied with pipework to provide clean water and compressed air and then to remove the earth in the form of a slurry. Using the grooved method can deliver a major advantage here. Its very flexibility means that piping can be readily modified as needed and extended quickly and easily as the tunnel progresses, enhancing the construction schedule.

Once built, a tunnel requires permanent services in the form of a fire main with hydrants located at intervals which the fire service will access in the event of fire, and maybe, other services such as heating, air conditioning and domestic water. Thermal movement is an important consideration in the design and installation of piping systems in addition to following the tunnel curvature.

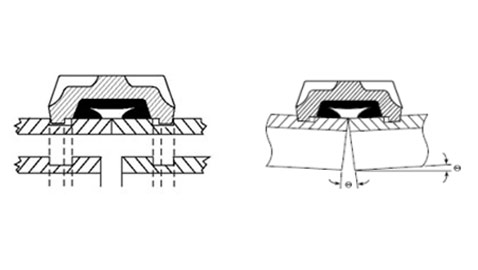

Figure A: linear movement & Figure B: angular deflection

Designers, engineers and contractors have used grooved piping systems to address these issues in tunnels across the globe. They include the award-winning Tunnel de Fréjus between France and Italy; the Sydney Cross City Tunnel in Australia; the Fort Smith Lake Tunnel Pipeline in Arkansas, USA; the A6B tunnel in Paris; the VielhaTunnel in Spain; and the Metro Warszawskieand Vistula Tunnel in Poland.

The need to keep the transport network operating as normal also means there is a very limited time overnight when work can be carried out. Grooved installation is helping to raise productivity and compress the schedule: with no cumbersome welding equipment to set up or remove from the job site, installing the pipework is much more time efficient and this flame-free joining method does not require the removal of hazardous fumes.

Linear movement and angular deflection

Grooved mechanical couplings are available with two distinct performance features: rigid and flexible couplings. Rigid mechanical couplings are designed to ‘fix’ the joint in its installed position, permitting no linear or angular movement at the joints. Flexible grooved mechanical couplings on the other hand are designed to allow controlled linear and angular movement at each joint that can accommodate pipeline deflection and piping thermal movement.

The design of the components enables grooved mechanical flexible couplings to allow for controlled movement in the pipe joint. Because the dimensions of the coupling key are narrower than the groove in the pipe, the coupling key has room to move in the pipe groove.

Thermal piping movement

Based upon the type of tunnel, there are two causes of thermal piping movement that require consideration. The first is from ambient temperature fluctuations due to the change in seasons. The second is from internal fluid temperature changes such as in heating and cooling systems.

There are four common methods for accommodating this thermal pipe movement in a grooved system: utilising the linear movement/deflection capabilities of flexible grooved couplings; providing an expansion joint utilising grooved mechanical pipe components; providing an expansion loop utilising grooved mechanical components; allowing the system to “free-float”.

The simplest, most common and cost-effective option is to use the angular deflection and linear movement capabilities of flexible couplings as the natural choice. Grooved mechanical couplings are a good alternative to welded U-shaped expansion loops and welded offsets. These couplings are easier and faster to install and take up less space.

A system which is to be installed using grooved couplings can be designed to take care of both curvature and thermal movement within the flexible couplings’ free range of motion so system stresses are minimised and without any additional components or piping configuration.

Efficient solution

In summary, grooved mechanical systems offer a range of efficient solutions to pipework installation challenges in tunnels. Grooved pipe joining provides effective time proven methods for accommodating tunnel curvature and thermal pipe movement, while at the same time reducing stresses on the piping system and decreasing system maintenance needs.

Additionally, the method helps to accelerate tunnelling projects, reduce costs and minimise job-site health and safety risks. Tunnels throughout the world are fitted with grooved piping systems, a testament to the practical engineering and economic benefits of this technology.