Flame-free grooved piping can slash health and safety risks, says Pankaj Soni, Country Manager, Victaulic India, a world leader in grooved and plain-end mechanical pipe joining systems, and fire protection systems.

Flame-free grooved piping can slash health and safety risks, says Pankaj Soni, Country Manager, Victaulic India, a world leader in grooved and plain-end mechanical pipe joining systems, and fire protection systems.

For many building owners, a contractor’s demonstrated safety performance is not only a prerequisite to inclusion in the bidding process, it is one of the significant factors in determining the outcome of the process. Savvy contractors are focusing more and more on injury prevention using zero injury techniques.

It is increasingly recognised that safety adds real value — it impacts people and it impacts the bottom line. In addition to the personal side of work injuries, safety affects contractors and owners, workers and managers, company reputations and even performance, productivity and profitability.Construction-related costs are both direct and indirect. Direct expenses include medical treatment, prescription drugs, weekly wage replacement and administrative costs. These costs may be covered by insurance, but indirect expenses are often more detrimental to the overall expense picture.Indirect expenses include interruption of work schedule, training of replacement workers, administrative time to investigate cause of injury and prepare reports, repair or replacement of damaged material, equipment or facility, and any required clean up of the accident scene addressing any resulting legal action, as well as increased insurance premiums or fines.

Safety-related costsToday, owners are paying close attention to all aspects of safety related costs — from the safety records of their contractors, including hiring and subcontracting practices, to the decision of whether to shut down during construction. Shutdowns create tremendous pressure to finish, and the probability of injury greatly increases.

Safety-related costsToday, owners are paying close attention to all aspects of safety related costs — from the safety records of their contractors, including hiring and subcontracting practices, to the decision of whether to shut down during construction. Shutdowns create tremendous pressure to finish, and the probability of injury greatly increases.

Victaulic, the world’s leading producer of mechanical pipe joining systems, conservatively estimates that jobs requiring welding applications demand up to 45 per cent more man-hours on average over its own no-flame piping solutions. The maths is simple: less man-hours equals less exposure and project risk.

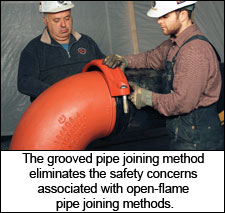

Mechanical pipe joining systems are easy to install and provide a union at every joint, giving contractors maximum field flexibility and enhanced on-site decision making capabilities. And as grooved mechanical pipe joining is a no-flame solution, it also requires no costly fire watch manpower or fire shielding, and no tanks, no torches and no potentially dangerous lead lines.

Mechanical pipe joining systems are easy to install and provide a union at every joint, giving contractors maximum field flexibility and enhanced on-site decision making capabilities. And as grooved mechanical pipe joining is a no-flame solution, it also requires no costly fire watch manpower or fire shielding, and no tanks, no torches and no potentially dangerous lead lines.

The grooved pipe joining method eliminates the safety concerns associated with open-flame pipe joining methods, delivering enhanced job site safety and cost savings for owners and contractors. Risks are reduced and pipe fitters are not exposed to the damaging fumes and serious health issues associated with hot works. Grooved piping systems mean safer jobsites for all.