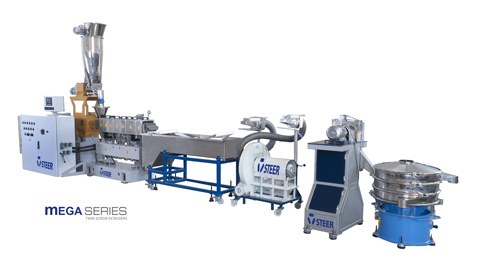

Photos: STEER

STEER, a creator of materials platform technologies, has announced that Japanese company Kohwa Kasei Chemicals, Inc. has procured a ‘Mega Special 40’ extruder line for its plant in Nara, near Osaka, a company release said.

Kohwa Kasei will use the Do/Di 1.55 Mega Special 40 for its engineering plastics application involving glass filled nylon. The company selected STEER for long-term collaboration as it is witnessing a surge in demand for nylon glass fibre filled polymers in Japan.

STEER Mega Special 40 is designed for high process compatibility, enhanced compounding, improved wear and corrosion performance, reduced cost of operations and maintenance.

A team of experts from Kohwa Kasei Chemicals led by its Chairman Shigenori Mochida-san visited STEER’s facilities in Bengaluru, Karnataka, and foundry in Coimbatore, Tamil Nadu, to understand STEER’s technology and to then deploy it gainfully in their production.

“We have gained a leadership position by having a complete range of products to cater to all types of market and application requirements in terms of production capacity, such as lab extruders, pilot production extruders or large extruders, and varied applications from commodity plastics to highly engineering material,” said Dr. Babu Padmanabhan, Managing Director and Chief Knowledge Officer, STEER Engineering.

He added, “The Japanese plastics industry has played a leading role in polymer development and application that spurred Japan’s advancement in appliances and consumer durables.”

STEER already serves over 225 Japanese compounding plants through its own facility in Japan and through its partnership with Kubota Corporation (for spare parts distribution). It also has an application development centre in Tokyo with ability to conduct application trials for new material development and to demonstrate the power of the process technology through STEER’s EPZ.

Started in 1993 in Dr. Babu Padmanabhan, STEER is a creator of materials platform technologies that effectively transforms and functionalises materials in the field of plastics, pharmaceuticals, food and nutraceuticals, biomaterials and biofuels. The company designs, develops, manufactures, markets, sells and services co-rotating twin screw extruder technology platform, along with all its major components including gearboxes, key peripherals such as volumetric and gravimetric feeders, side-feeders, screen changers and processing section parts such as elements, barrels and shafts for customised application solutions.

STEER, platform technology helps compounders develop perfect colour master batch, engineering plastics, speciality plastics, commodity plastics, thermoplastic elastomers, recycle plastics and conductive plastics.

Source: STEER Engineering Pvt. Ltd