Several elements play an important role in the successful construction of hydropower plants, says Scott McDonald, a power specialist with Victaulic, the world-leading manufacturer of mechanical pipe joining systems.

Several elements play an important role in the successful construction of hydropower plants, says Scott McDonald, a power specialist with Victaulic, the world-leading manufacturer of mechanical pipe joining systems.

As interest in hydroelectric power increases, all signs are pointing to growth in the construction of plants, especially small projects to add generating capacity to existing dams. The factors that make these projects successful are not unlike those that make any industrial construction project successful: communication and coordination, threat assessment and consideration of new technologies. Each of these elements plays an important factor in hydroelectric construction.

Firstly, communication with all stakeholders and careful project coordination are key. Consistent and ongoing communication must happen not just between owners, engineers and contractors, but also vendors, suppliers and the public. Don’t categorically dismiss supplier recommendations to over-order materials. It may seem an unnecessary expense, but 10 per cent more material covers your “oops factor.” Even if torrential rain washes out a portion of the penstock mid-construction, the project can stay on schedule, keeping you on track for that completion bonus. Cover yourself on the front end so you don’t lose on the backend.

Don’t forget the public! Keep in mind that their opinions of hydro projects range from clean and green to environmentally destructive. Keep them appraised, not just of the construction schedule, but of the benefits of hydropower. Localise your messages as much as possible. Will the new capacity reduce the cost of electricity? Will the project employ local labourers or pump money into the local economy?

An important part of communication and coordination is lean construction. Lean construction, a widely used practice in other sectors, seeks to eliminate inefficiencies and waste, and improve productivity and process and material flow through concepts such as pre-planning and prefabrication.

Pre-planning includes the use of 3D modelling and/or building information modelling (BIM). Use of these techniques can eliminate challenges that exist in the construction process, such as clash detection and trade coordination. Mechanical, electrical and other contractors compete for available space and make changes based on the realities of the jobsite.

Even with the best intentions for collaboration, these changes are often made independent of other contractors, leading to conflicts, delays and additional costs. Resolving conflicts prior to arrival at the jobsite results in significant cost and time savings, and speeds the construction process. In fact, every rupee spent on project design and construction pre-planning can save as much as Rs.4 in the field.

Prefabrication involves driving as much of the construction as possible into the controlled environment of a fabrication shop and out of the field to reduce costs, mitigate risk factors such as weather and labour and reduce material handling at the jobsite. It is much more efficient to build a pipe spool, for example, in a shop environment, than in the field. In fact, gains in productivity by as much as 20 times are possible when using mechanical joining methods such as grooved piping in the shop.

Prefabrication involves driving as much of the construction as possible into the controlled environment of a fabrication shop and out of the field to reduce costs, mitigate risk factors such as weather and labour and reduce material handling at the jobsite. It is much more efficient to build a pipe spool, for example, in a shop environment, than in the field. In fact, gains in productivity by as much as 20 times are possible when using mechanical joining methods such as grooved piping in the shop.

The second element of success in hydro plant construction is threat assessment. Such threats include availability and quality of skilled labour, weather and safety. Skilled labourers such as welders are in short supply, and with many highly experienced individuals reaching retirement age, declines in quality may result. Furthermore, economic shifts can redirect skilled labour to another sector.

For example, as part of the National Shipbuilding Procurement Strategy, the Canadian government recently awarded $33 billion (approximately Rs.1,800 billion) worth of contracts to renew Canada’s federal fleet of combat and non-combat ships over the next 20 years. A programme of this magnitude will necessitate a number of highly skilled labourers in long-term positions, and could draw those individuals from the relatively unstable construction industry.

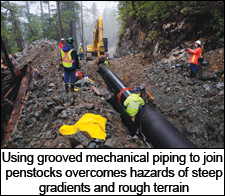

Weather is also a risk factor. Construction activities such as welding may be difficult in rainy conditions, and limited or even prohibited in extremely dry conditions when the risk of forest or brush fire is high.

Safety is also a concern. As many steps as we take to prevent accidents, they can occur, and the environments in which hydroelectric plants are built are rife with additional hazards such as elevation changes and rough terrain. Speciality jobs such as re-lining penstocks are also potentially hazardous.

Mitigation of risks through consideration of new and alternative technologies must also be considered. Considering alternatives such as grooved mechanical piping to join penstocks and other piping systems eliminates the need for welding on a significant portion of the project.

There are, of course, many more factors that play a role in whether a project will be a success, but these serve as reminders, particularly as the interest in hydro renews, that the stakes are high and we shouldn’t leave anything to chance.